Superconducting Films for Particle Acceleration

Researchers demonstrated record accelerating cavity performance using a technique that could lead to significant cost savings.

The Science

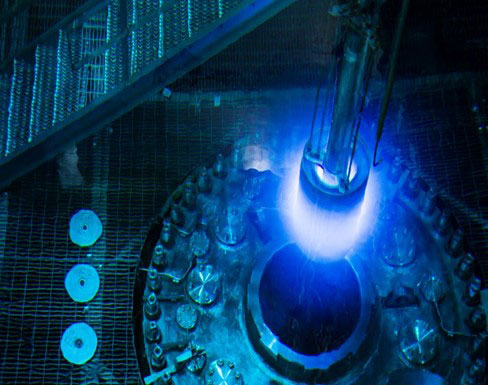

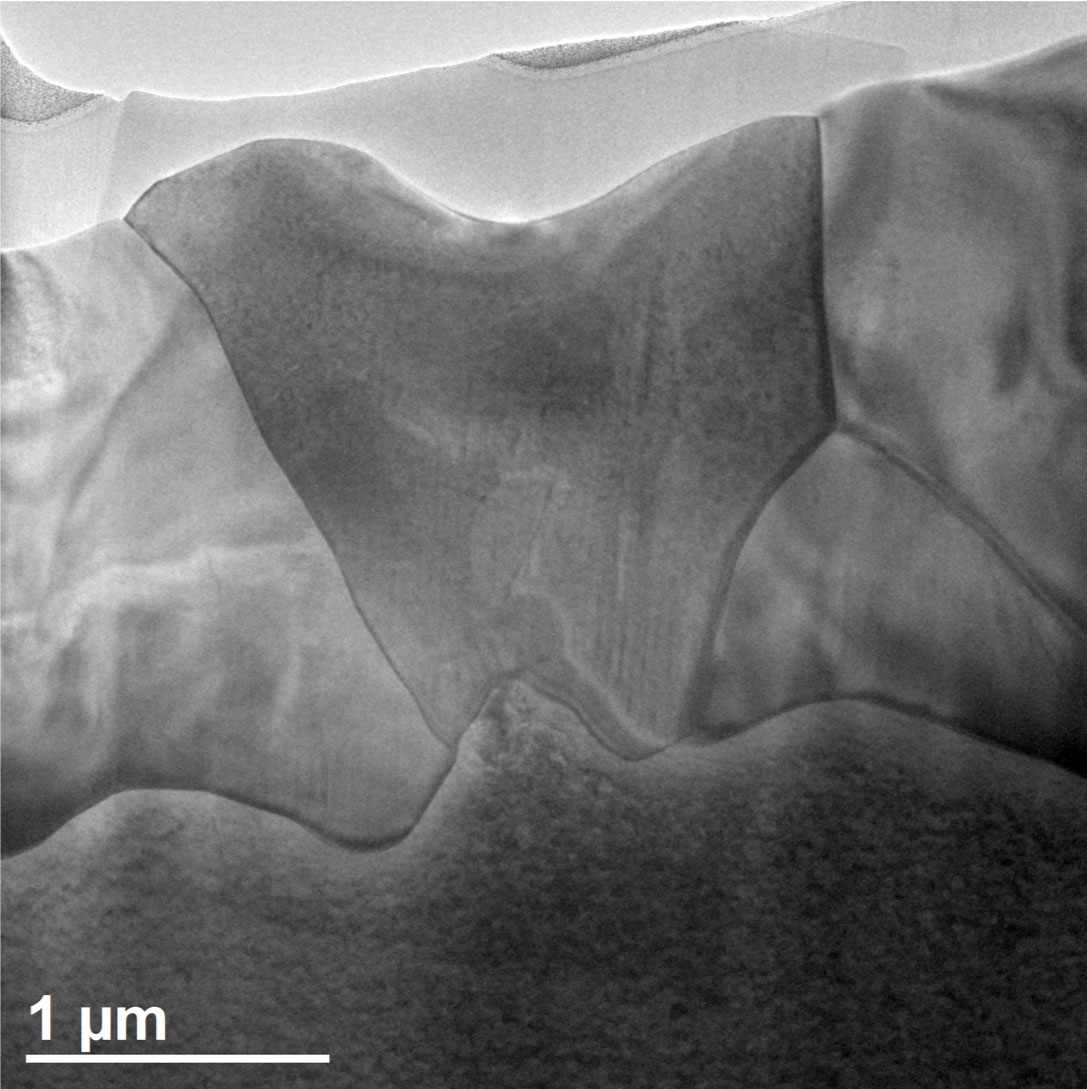

Superconducting radio-frequency (SRF) cavities are the “muscle” of many modern particle accelerators. By cooling these devices to about minus 452 degrees Fahrenheit and inputting electric power, SRF cavities increase the energy of beams of charged particles passing through them. Making cavities out of superconducting materials dramatically increases their efficiency. These materials allow cavities to accelerate beams to high energies over short distances, without long pauses between beam pulses. In a new study, scientists coated a cavity with a film of niobium-tin, a promising superconducting material.

The Impact

High-efficiency particle accelerators benefit basic science. Also, they could save money for industry. How? Tabletop accelerators wouldn’t require a large, expensive cooling plant. More broadly, niobium-tin cavities could improve bigger accelerators, reducing infrastructure and operating costs. And that’s not the end. What if scientists could push the performance of coated cavities further, closer to the predicted ultimate potential of the material? If so, it could open opportunities in high-energy physics and X-ray science.

Summary

In this study, scientists and engineers apply a thin film of niobium-tin (Nb3Sn) to the inside of a niobium accelerating cavity to improve its efficiency. The low-frequency cavity used in this study has certain advantages, including cryogenic efficiency, the ability to accept larger beam sizes, and the ability to accelerate particles in a wide range of velocities below the speed of light. On the other hand, at lower frequencies, cavities tend to be larger, meaning more surface area to coat with Nb3Sn, which can make the coating process more challenging. A team coated a 650-MHz single-cell cavity of a style that will operate in the upcoming PIP-II accelerator at Fermilab. This was the group’s first attempt to coat a low-frequency cavity. They achieved record performance for a cavity of this type. Crucially, the cavity shows very high quality factor at temperatures in the range of minus 450 to 452 degrees Fahrenheit (4 to 5 Kelvin), about 10 times higher than before coating, when it was a standard niobium cavity. While these results show promise for small-scale accelerator applications, with additional development, Nb3Sn cavities have the potential to impact large-scale accelerators as well.

Contact

Sam Posen

Fermilab

sposen@fnal.gov

Funding

This work is supported through the Fermilab Laboratory Directed Research and Development program, the Department of Energy Office of Science’s Office of High Energy Physics, and the U.S. Army Engineer Research and Development Center.

Publications

S. Posen and D.L. Hall, “Nb3Sn superconducting radiofrequency cavities: Fabrication, results, properties, and prospects.” Superconductor Science and Technology 30, 1 (2017). [DOI: 10.1088/1361-6668/30/3/033004]

Related Links

Fermilab news release: Fermilab scientists Sam Posen, Jen Raaf win prestigious DOE Early Career Research Awards

Fermilab news release: Concrete applications for accelerator science

Highlight Categories

Program: HEP

Performer: University , DOE Laboratory

Additional: Collaborations , Non-DOE Interagency Collaboration