2017 R&D 100 Award Winners

The Department of Energy Office of Science's national laboratories had 22 technologies recently chosen as 2017 R&D 100 Award Winners. Each year, R&D Magazine recognizes the most outstanding technology developments with promising commercial potential. The coveted awards – now in their 55th year – are presented annually in recognition of exceptional new products, processes, materials, or software that were developed throughout the world and introduced into the market the previous year. R&D 100 awards are selected by an independent panel of judges based on the technical significance, uniqueness, and usefulness of projects and technologies from across industry, government, and academia. Congratulations to the Office of Science's national laboratories!

2017 R&D 100 Award Winners

Office of Science Laboratory: Argonne National Laboratory

Other Partners: N/A

Name of Project: Oleo Sponge

Argonne National Laboratory's Oleo Sponge offers a new way to clean up oil spills in water. Built using low-cost materials and processing methods, Oleo Sponge absorbs up to 90 times its weight in oil. In addition, it's reusable and collects oil above and below the water's surface. Manufactured by chemically treating commercial foam so that it attracts oil and repels water, it rapidly and selectively absorbs oil from an oil/water mixture. It is the only mainstream technology for cleaning up sub-surface oil droplets suspended in the water column.

Office of Science Laboratory: Argonne National Laboratory

Other Partners: N/A

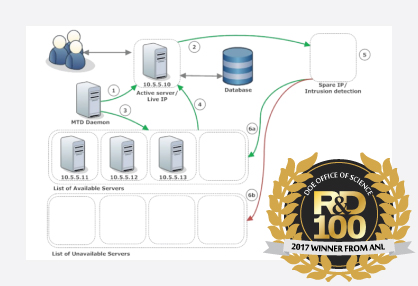

Name of Project: MORE-MTD

The Multiple Operating system Rotation Environment Moving Target Defense (MORE-MTD) software enhances computer system security by rotating through multiple operating systems. Because attackers cannot predict the software the computer will be using, the system increases the uncertainty and cost of attacking while reducing the likelihood of an attacker locating a vulnerability. The rotating operating systems help isolate and protect back-end data stores. In particular, the system defends against hackers exploiting "zero-day" vulnerabilities, when a hacker finds a previously unknown vulnerability in computer software.

Office of Science Laboratory: Lawrence Berkeley National Laboratory

Other Partners: China Energy Group of Berkeley Lab and the Energy Research Institute of China's National Development and Reform Commission; Shandong Academy of Sciences.

Name of Project: Benchmarking and Energy Saving Tool for Low-Carbon Cities (BEST Cities)

Home to more than half of humanity, cities produce nearly 70 percent of the globe's energy-related greenhouse gas emissions. To reach a low-carbon future, urban centers need strategies that cut energy use and enhance resilience. The Benchmarking and Energy Saving Tool for Low-Carbon Cities (BEST Cities) provides software for urban planning that users can easily install and run. This integrated, computer-based tool helps local policymakers and planners assess their city's energy use and related emissions, compare the performance to similar cities, and develop a plan with specific policy strategies that reduce carbon and methane emissions. The software is available in both English and Chinese.

Office of Science Laboratory: Lawrence Berkeley National Laboratory

Other Partners: N/A

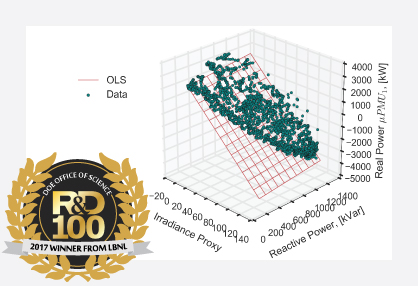

Name of Project: Distributed Solar Estimation (DiSE)

As more homes and businesses adopt solar energy, utilities and grid operators need real-time insights into how these new, highly variable resources are affecting the electrical grid. The Distributed Solar Estimation (DiSE) algorithm makes it possible for the first time to accurately estimate electricity output from customer-owned photovoltaic solar panels. DiSE can help system operators anticipate and prepare for short-term changes in power level and avoid buying too much energy. This software improves grid reliability while reducing ratepayers' costs. DiSE also boosts security by helping the grid operate reliably without requiring every inverter communicate its power generation to the grid in real time.

Office of Science Laboratory: Lawrence Berkeley National Laboratory

Other Partners: University of Illinois-Champaign

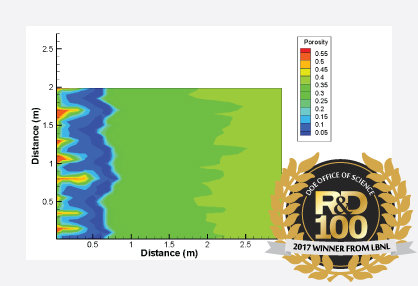

Name of Project: CrunchFlow

CrunchFlow is a software package that simulates how chemical reactions occur and change as fluids travel underground. CrunchFlow includes a number of chemical and physical processes that similar products do not, such as changes in how easily water can move through rocks. All of these features are available in a single package that users with a variety of expertise can run on a desktop computer. With CrunchFlow's computational efficiency, scientists can achieve high spatial resolution while extending simulations far back in geologic time. By improving the accuracy of a range of Earth and environmental sciences applications, CrunchFlow helps scientists better understand current and past ecological systems below the Earth's surface.

Office of Science Laboratory: Lawrence Berkeley National Laboratory

Other Partners: N/A

Name of Project: Double Barcoded Shotgun Expression Library Sequencing (Dub-seq)

Double Barcoded Shotgun Expression Library Sequencing (Dub-seq) is a technology for discovering the functions of genes in microbes under different environmental conditions. Because Dub-seq can process large amounts of genetic information at once, it is faster, cheaper, more flexible, and requires less work than previous genetic analysis technologies. Scientists can adapt it to a variety of biotechnologies, such as discovering new enzymes, finding new cancer drugs, gaining insight into resistance to viruses, and understanding how antibiotics act on microbes that cause disease.

Office of Science Laboratory: Oak Ridge National Laboratory

Other Partners: Fiat Chrysler Automobiles US LLC; Nemak U.S.A. Inc

Name of Project: ACMZ Cast Aluminum Alloys

Lightweight, high-temperature aluminum alloys will play a vital part in improving automotive fuel efficiency in the future. Common commercial alloys soften rapidly at high temperatures, limiting how manufacturers can use them in vehicles. In contrast, alloys that can withstand elevated temperatures are prohibitively expensive and difficult to cast. ACMZ cast aluminum alloys are affordable, lightweight superalloys. They withstand temperatures of almost 100 degrees Celsius, more than current commercial alloys, while providing equivalent mechanical performance. Their properties can meet the varied demands of different automotive engine components. They are also strong enough for manufacturers to use them in next-generation high-efficiency combustion engines.

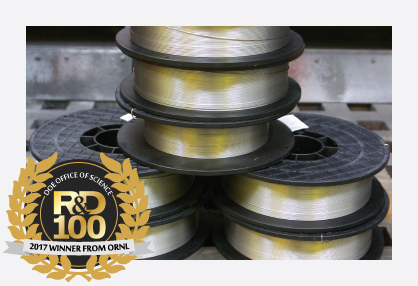

Office of Science Laboratories: Oak Ridge National Laboratory; Ames Laboratory

Other Partners: Critical Materials Institute; Magnet Applications Inc.; Tru-Design LLC; Momentum Technologies

Name of Project: Additively Printed High Performance Magnets

For the first time, Oak Ridge National Laboratory used its Big Area Additive Manufacturing (BAAM) method to 3D print Additively Printed High Performance Magnets. In contrast to more common sintered magnets that require manufacturers to apply very high pressure to chemically reactive materials, bonded magnets are less expensive and less resource-intensive to produce. The bonded magnets made using BAAM have superior magnetic performance and tensile strength compared to bonded magnets produced by other methods. They can be fabricated into intricate shapes with no size limitations. Because the manufacturing process consumes less energy than other technologies and generates almost no rare-earth material waste, it is also more economic and sustainable.

Office of Science Laboratory: Oak Ridge National Laboratory

Other Partners: U.S. Army Tank Automotive Research Development and Engineering Center

Name of Project: Filler Materials for Welding and 3D Printing

Oak Ridge National Laboratory's innovative filler materials were created to minimize the residual stresses and distortions caused by the heating and melting processes of welding and 3D printing. This stress manifests as hydrogen-induced cracking or embrittlement, which can cause catastrophic structural failure and normally requires costly, labor-intensive heat treatments to avoid. The filler material is designed to counterbalance thermal shrinkage and control residual stresses and distortions without heat treatments, saving money on future repairs and improving the component's durability and service life. This technology can be used revitalize aging infrastructure and avoid the human, environmental and financial impacts of massive structural failures.

Office of Science Laboratory: Oak Ridge National Laboratory

Other Partners: University of Rochester

Name of Project: SAFIRE – Safe Impact Resistant Electrolyte

Oak Ridge National Laboratory's Safe Impact Resistant Electrolyte (SAFIRE) improves the safety of plug-in electric vehicle batteries. In typical automotive lithium-ion batteries, the liquid electrolyte (which conducts the electrical current) poses a fire risk in high-speed collisions. To minimize this risk, current plug-in electric vehicles use heavy shielding that reduces their range and efficiency. In contrast, the SAFIRE electrolyte eliminates this risk by using an additive that transforms the liquid electrolyte to a solid upon impact. By blocking contact between electrodes, it prevents short circuiting and a potential fire. Under normal conditions, SAFIRE performs as well as conventional electrolytes. In vehicles, it has the potential to significantly reduce electric vehicle weight and increase travel range.

Office of Science Laboratory: Oak Ridge National Laboratory

Other Partners: SepQuant, Inc.

Name of Project: dropletProbe Surface Sampling System for Mass Spectrometry

The dropletProbe system, developed with support from Oak Ridge National Laboratory, is a completely new means of surface sampling for mass spectrometry, a major scientific technique for measuring the masses of chemicals in a sample. The dropletProbe system provides rapid, simple chemical extraction and analysis for a host of scientific applications. It is a low cost, low-maintenance, and nondestructive method for sampling complex analytical surfaces, such as biological tissue samples. It provides scientists with a high degree of precision for targeting specific areas on the sample. By reducing cost and improving accuracy, this tool should help increase the pace of scientific discovery.

Office of Science Laboratories: Oak Ridge National Laboratory; Ames Laboratory

Other Partners: Eck Industries; Lawrence Livermore National Laboratory; Critical Materials Institute

Name of Project: ACE: The Ageless Aluminum Revolution

Lightweight materials such as aluminum alloys can help substantially increase the efficiency of vehicles and airplanes. ACE is a new family of aluminum alloys that exhibits better performance at high temperatures and is easier to cast than previous alloys. By combining aluminum and cerium, or a similar element, with traditional alloying materials, ACE is better able to resist corrosion and be stretched into wires. ACE alloys remain stable at temperatures 300 degrees Celsius higher than leading commercial alloys. They can also withstand 30 percent more tension before they deform. Manufacturers can successfully cast ACE alloys in a wide variety of structural components without energy-intensive heat treatments. Eliminating these treatments could significantly increase production output and reduce manufacturing costs in some cases by almost 60 percent.

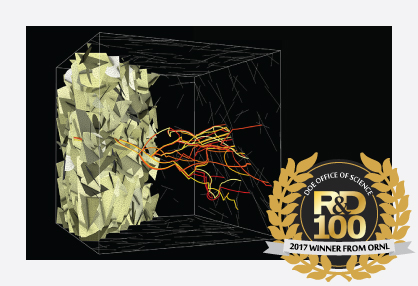

Office of Science Laboratory: Oak Ridge National Laboratory

Other Partners: Los Alamos National Laboratory

Name of Project: dfnWorks

dfnWorks is a software suite that generates 3D models of how rocks fracture as well as how fluids move through those fractures. Research into safely managing historical nuclear waste, conducting hydraulic fracturing, and storing carbon dioxide (CO2) underground rely on this type of software. But because these models can be incredibly complex, they often require a great deal of computational time and power to run. Compared to similar programs, dfnWorks requires less time to run and allows scientists to model geological conditions that they couldn't previously. Scientists have used dfnWorks to model a variety of systems, from those that are only a few millimeters in size up to those that are entire kilometers wide.

Office of Science Laboratory: Oak Ridge National Laboratory

Other Partners: Tru-Design, LLC; Polynt Composites

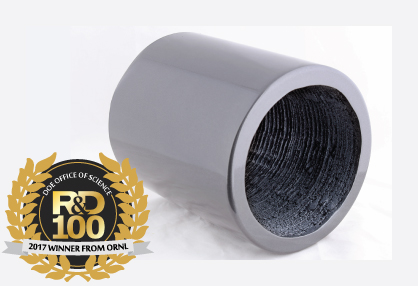

Name of Project: Large-Format Additive Coating Solutions

Large-scale 3D printing can quickly produce prototypes and molds used to manufacture parts, but these pieces are often neither smooth nor vacuum tight. As a result, manufacturers can't use these molds to produce composite components, parts made of several different types of materials. As manufacturing increasingly focuses on composite parts, this challenge limits the usefulness of 3D printing. The Large-Format Additive Coating Solutions, TD Coat RT and TD Seal HT, minimize this problem. Using a nano-scale filler, they cover the rough exterior of a printed part and create an unbroken vacuum-tight seal.

Office of Science Laboratory: Oak Ridge National Laboratory

Other Partners: Techmer PM; BASF

Name of Project: TEAMM- Electrafil PPS 3D; Electrafil PPSU 3D

Techmer Engineered Additive Manufacturing Materials (TEAMM) are new plastic and carbon fiber compounds that are especially designed for 3D printing. With 3D printing and an autoclave, manufacturers can use these materials to produce molds for composite panels and parts. The company offers two different types of TEAMM. Each type has different proportions of carbon fiber (25 percent and 50 percent), which provides a variety of mechanical properties for a range of applications. Using these compounds, large-scale aerospace companies can produce molds for a tenth of the cost and lead time compared to existing technology. Other applications include defense and high-end automotive markets.

Office of Science Laboratory: Pacific Northwest National Laboratory

Other Partners: Arkema Inc.

Name of Project: Multibed Adsorption Recuperative Cooling (MARCool) System

Pacific Northwest National Laboratory and Arkema Inc. have developed the Multibed Adsorption Recuperative Cooling (MARCool) System, a new class of solid-state cooling technology that operates off of wasted heat. This new product could lead to significant energy and cost savings in homes, buildings, cars, trucks, and industrial processes. Currently, most air conditioners use tremendous amounts of energy. In fact, 15 percent of U.S. energy usage goes towards cooling. Adsorption technology, which uses heat to drive the cooling process instead of electricity, offers an alternative. However, traditional adsorption coolers are too large, heavy, and expensive to use in most situations. In contrast, MARCool is half of the size and twice as efficient as standard adsorption chiller systems. In addition, most of its components are already commercially available and it works with standard refrigerants on the market.

Office of Science Laboratory: Pacific Northwest National Laboratory

Other Partners: N/A

Name of Project: Acoustic Gunshot Detection Technology

Active-shooter detection systems are generally designed for outdoor, urban environments. But now, researchers at Pacific Northwest National Laboratory have created a gunshot detector specifically for indoor environments such as schools and public buildings. The small, inexpensive device is battery-powered and connects wirelessly to existing security systems. It can distinguish between gunshots and other sounds. Once a shot is fired, the sensor immediately activates the building's lockdown and emergency notification procedures. SecurityUSA Services has licensed the Acoustic Gunshot Detection Technology the PNNL technology. SUS' version of the sensor is integrated into its security products. Once a shot is fired their system activates lockdown procedures and notifies police. The company expects to deliver commercial products in 2017.

Office of Science Laboratory: Pacific Northwest National Laboratory

Other Partners: N/A

Name of Project: Friction Stir Scribe Process for Joining Dissimilar Materials

To reduce fuel consumption, U.S. automakers are incorporating lightweight materials into new vehicles. But manufacturers using conventional processes, such as welding, can't join dissimilar materials with different melting points without sacrificing strength, durability, or safety. Pacific Northwest National Laboratory's Friction Stir Scribe Process addresses this challenge. It is the first technology that makes it possible to join materials with drastically different melting points in a continuous, linear, or curved manner without needing additional adhesives, bolts, and rivets. Using this tool, manufacturers can now incorporate new and different materials into a variety of strong, lightweight parts, such as sub-frames for the engine chassis, without sacrificing strength or durability.

Office of Science Laboratory: Pacific Northwest National Laboratory

Other Partners: IRsweep

Name of Project: IRcell

Scientists need to rapidly identify trace gases when detecting toxic industrial chemicals, identifying disease indicators, or monitoring for possible proliferation of nuclear or chemical weapons. Current approaches don't always provide the measurement sensitivity and resolution needed to detect tiny amounts of toxins hiding among larger volumes of more benign gases. Pacific Northwest National Laboratory's compact, patented IRcell technology is a dramatic improvement to traditional detection methods. Compared to current technologies, its design provides greater sensitivity and speed. In addition, it requires only a tiny sample volume for analysis and is compact enough to be used in the field.

Office of Science Laboratory: Pacific Northwest National Laboratory

Other Partners: N/A

Name of Project: SerialTap

Most cybersecurity tools and methods are highly sophisticated, designed to protect critical data from attackers around the globe. But some older industrial control systems, such as those that manage the operation of transportation systems and the delivery of water and electricity, cannot interact with today's cybersecurity tools. SerialTap, created by Pacific Northwest National Laboratory, is designed to protect these legacy systems. The palm-sized device is an inexpensive, non-intrusive add-on that can monitor and verify the activity in older serial communication systems. A startup company, Cynash, licensed the technology and is commercializing it.

Office of Science Laboratory: Pacific Northwest National Laboratory

Other Partners: None

Name of Project: Structures for Lossless Ion Manipulations (SLIM)

Medical researchers need to quickly distinguish characteristics of different molecules in biological samples such as blood. But standard analytical and separation technologies are slow, cumbersome, and expensive. In addition, they can't always distinguish between molecules with similar masses but different structures. Pacific Northwest National Laboratory's Structures for Lossless Ion Manipulations (SLIM) technology is 1,000 times faster than current methods and can identify trace differences in samples as small as a single cell. A startup, MOBILion, is commercializing SLIM, to create a compact version that doctors could use to provide biomarker-based disease results to patients.

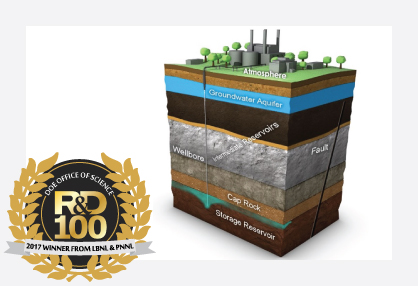

Office of Science Laboratories: Pacific Northwest National Laboratory; Lawrence Berkeley National Laboratory

Other Partners: National Energy Technology Laboratory; Los Alamos National Laboratory; Lawrence Livermore National Laboratory

Name of Project: National Risk Assessment Partnership (NRAP) Toolset

Deep underground geologic formations offer promising places to safely and effectively store large volumes of carbon dioxide (CO2) generated from burning coal, oil, and natural gas. The National Risk Assessment Partnership (NRAP) Toolset is the first complete suite of computer software that models possible environmental risks from potential storage sites, such as fluid leakage and earthquakes. The Toolset draws on the expertise of five DOE national laboratories and is being used by more than 250 stakeholders from academia, regulatory agencies, and industry.

2017 R&D 100 Award Finalists

Office of Science Laboratory: Argonne National Laboratory

Other Partners: N/A

Name of Project: Smart Charge Adapter (SCA)

Argonne National Laboratory's Smart Charge Adapter (SCA) can convert any plug-in electric vehicle AC charging station into a smart charging station able to communicate with the electric grid. By allowing utilities greater control over the process, smart charging stations give utilities the ability to better manage loads on the grid. The SCA enables charging station operators to remotely control the entire process, including scheduling charging, measuring usage, and billing users. It has built-in Wi-Fi communication and the ability to seamlessly stop, start, and increase or decrease the charging level of any charge session. The SCA will work with plug-in electric vehicle/charge station combinations without requiring that an electrician upgrade either the vehicle or the charging station.

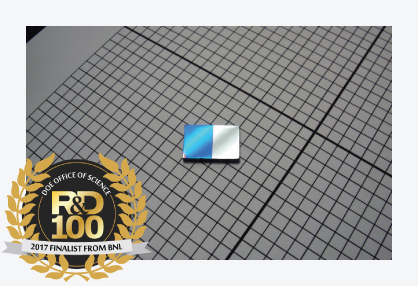

Office of Science Laboratory: Brookhaven National Laboratory

Other Partners: Norfolk State University

Name of Project: CZT ElectrodeBoost

Brookhaven National Laboratory, in collaboration with Norfolk State University, developed a new, non-metallic electrode contact that can replace the conventional contacts used in nuclear radiation detectors. Prior to this discovery, contacts in commercial x-ray and gamma-ray detectors exclusively used noble metals such as gold or platinum. The new contact resolves many of the conventional metal contacts' long-standing technological problems, including poor adhesion and electrical noise that decrease the detectors' performance over time. These detectors are used in a variety of fields, including homeland security, medical imaging, gamma telescopes, oil and mineral exploration, and environmental and food monitoring.

Office of Science Laboratory: Lawrence Berkeley National Laboratory

Other Partners: N/A

Name of Project: MyGreenCar

MyGreenCar is a smartphone app that offers an accurate, tailored virtual test drive to consumers thinking about buying more fuel-efficient cars. The app predicts and summarizes fuel costs, fuel economy, battery life, and other attributes of a car based on an individual's real driving style and habits. By giving buyers personalized, easy-to-understand data on the value of fuel-efficient vehicles, MyGreenCar is helping accelerate the adoption of greener models that produce fewer greenhouse gas emissions.

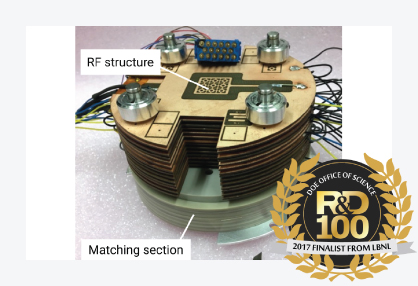

Office of Science Laboratory: Lawrence Berkeley National Laboratory

Other Partners: Cornell University

Name of Project: MEMS-ACCEL - Microelectromechanical-Systems-Based Particle Accelerator

Particle accelerators are critical to discovery research, medical applications and industrial uses, such as semiconductor manufacturing. The Microelectromechanical-Systems-Based Particle Accelerator (MEMS-ACCEL) is a miniaturized, low-cost, high-current particle accelerator. This technology is substantially less expensive than similar products because it uses components that can be mass fabricated. Because the technology uses lower voltages, it has a simpler design and lower operating costs than other technologies on the market. These features and the fact that researchers can scale the technology up to higher currents if necessary makes it possible for researchers to use it across a wide range of applications.

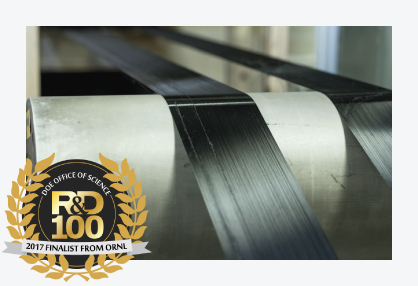

Office of Science Laboratory: Oak Ridge National Laboratory

Other Partners: N/A

Name of Project: Low Cost Carbon Fiber (LCCF)

Carbon fiber has historically been a high-priced specialty material, which has limited its widespread use. Oak Ridge National Laboratory's Low Cost Carbon Fiber (LCCF) production method makes high-strength carbon fiber comparable to commercially available material at approximately half the finished product cost. It is also much faster than other methods and reduces energy usage by about 50 percent. Manufacturers can also combine LCCF with plastic materials to produce lightweight composites. This product can potentially make carbon fiber an affordable material for high-volume, cost-sensitive applications such as fuel-efficient automobiles and wind turbine blades.