New Composite Anode Material for High-Performance Li-Ion Batteries

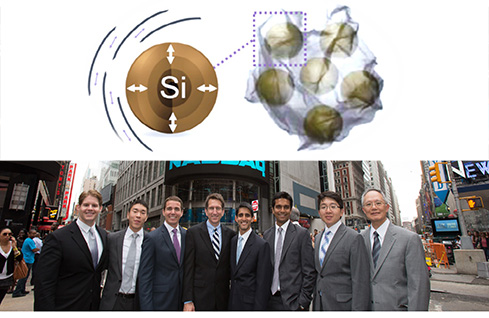

SiNode’s core technology allows a battery to store more lithium, thereby charging faster and lasting up to 40% longer than conventional batteries

SiNode Systems’ founding team in Times Square after ringing the NASDAQ closing bell.

R&D Opportunity

Lithium-ion batteries are the go-to energy supply for most consumer and home electronics, due to their high energy density and low self-discharge. The electric vehicle market is perhaps set to be the biggest consumer of rechargeable lithium-ion batteries. Most newer plug-in hybrids and all-electric vehicles opt to use them over the nickel-metal hydride batteries used in older hybrid vehicles. Addressing this global demand, SiNode produces an advanced composite material made of silicon and graphene (a form of carbon). The composite enables higher performing lithium-ion batteries for electric vehicles and many consumer electronic applications.

Among clean-tech startups, SiNode Systems, Inc. stands out for its remarkable birth story. It was founded in 2012 by a multidisciplinary team of students fresh out of an energy and entrepreneurship course offered by Northwestern University. It wasn’t long before the company received its first U.S. Department of Energy (DOE) Small Business Innovation Research (SBIR) grant. “We succeeded in writing a sound business plan and, at the end of the class, decided to apply for the Department of Energy’s SBIR award,” said Samir Mayekar. He was one of the graduate students on the Northwestern University team and is now Chief Executive Officer of SiNode.

Solution

SiNode’s core technology was developed at one of the DOE Energy Frontier Research Centers (EFRCs) — the Center for Electrical Energy Storage (CEES). The center is at Argonne National Laboratory (in partnership with Northwestern University). The core technology allows a battery to store a greater amount of lithium, thereby charging faster and lasting longer than conventional batteries. Current graphite-based anodes offer a capacity of 372 mAh/g. SiNode’s material can be customized to achieve capacities between 1000 mAh/g and over 2500 mAh/g, delivering higher cell level energy density. In addition, in-plane nano-engineered porosity in the graphene layers allows rapid ionic diffusion through the structure for faster charging.

SiNode’s success and competitive advantage over similar firms is due to several factors. First, both the chemical elements (carbon (C) and silicon (Si)) and the process used to assemble the anode material are low in cost. In addition, the new anode material can be easily incorporated into the existing battery design, without modifying the production process. Finally, SiNode was conceived with a defined customer focus. The relationship with customers started when the team was still in the Commercialization Lab at Northwestern University. The company was built to address customers’ needs from the very beginning.

“Customers saw value in what we were proposing and were willing to fund us in order to have access to our technology before their competitors,” Mayekar explained. The customers Mayekar refers to are top tier consumer electronics and automotive companies. These companies became interested in SiNode once the team of young entrepreneurs won the DOE SBIR award.

“The SBIR award gave us that stamp of approval big companies were looking for before they started talking to us,” said Mayekar. “The SBIR award gave us not only the credibility needed to enter the electric vehicle battery field, but it also provided the catalytic funds necessary to spin out of the university, to acquire office space and hire our first full time employees. SBIR was indispensable to bridge the gap to the market, and without it SiNode would not be where we are today.”

Impact

At the conclusion of the Phase II SBIR award, SiNode has 15 employees and exports about 90% of their products to Japan and Korea. The company has received follow-on investments and revenues amounting to over 5 times the original DOE SBIR investment. This includes a $4-million contract awarded by the United States Advanced Battery Consortium LLC (USABC). The USABC is a collaborative organization of FCA US LLC, Ford Motor Company, and General Motors, with a 50% cost-share funded by DOE. The 30-month program outlined in the contract will focus on

- the development of silicon-graphene high-energy anode material appropriate for vehicle applications.

- the development and scale up of pouch cells. These cells will exhibit anode performance metrics that exceed the minimum USABC targets for electric vehicles.

SiNode products are being assembled and tested in batteries for electric vehicles, smart phones, and other applications in partnership with various corporations. Once in the market, the first-generation SiNode anode will deliver a 40% increase in battery energy density. This increased density translates into an increased range for an electric car or usage time for a smart phone.

Contact

Samir Mayekar, CEO, SiNode

samirmayekar@sinode-systems.com, www.sinodesystems.com