Using Protons to Peer into Metal Solidification

Proton radiography is a new tool for imaging melting and solidification of metals.

The Science

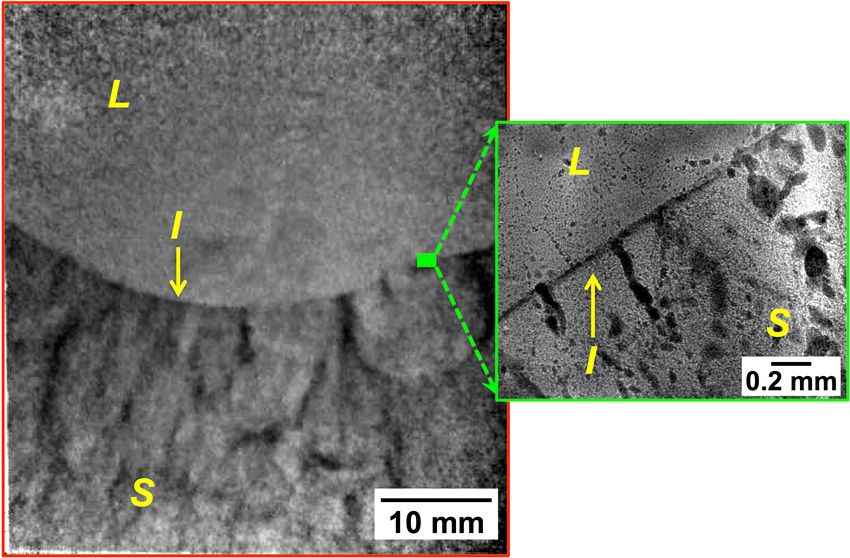

For the first time, high-energy protons have been used to image a large metal sample during melting and solidification without destroying the sample.

The Impact

Direct imaging of solidification will enable fundamental understanding of solidification to inform manufacturing and provide insights needed to predictively control metal processing to obtain desired structures and properties.

Summary

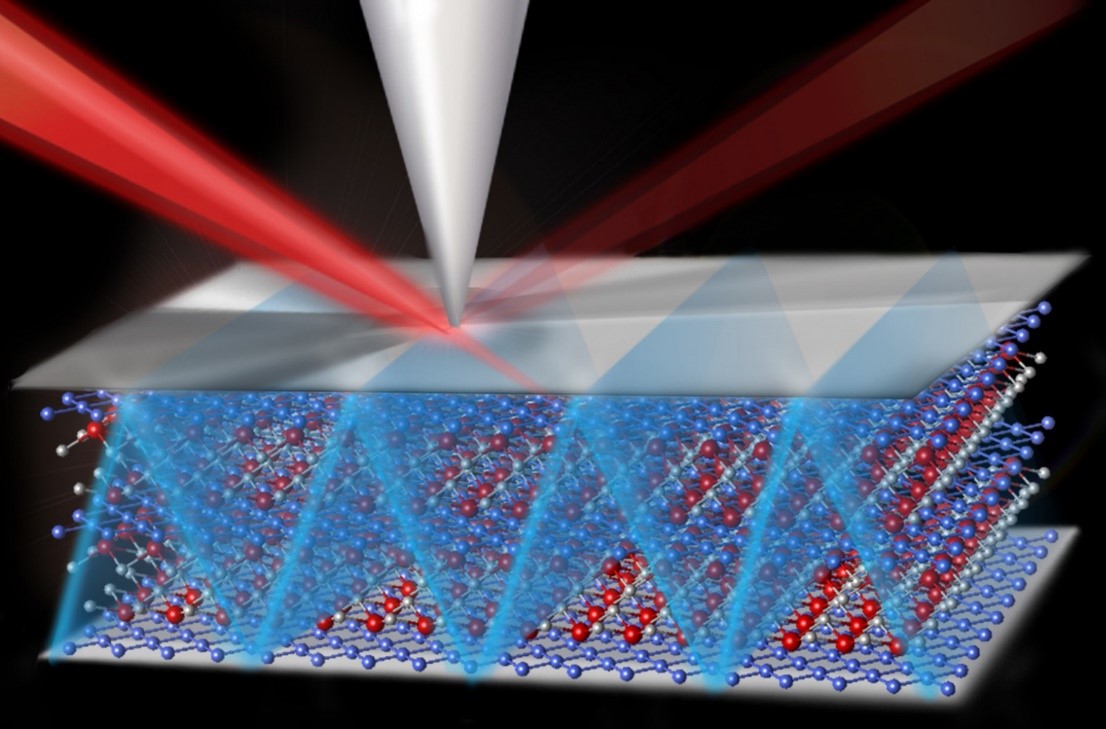

For the first time, high-energy protons have been used to image a large metal sample during melting and solidification without destroying the sample. The real-time imaging will provide the key understanding to control the microstructure of metals, critical information needed to inform manufacturing processes in order to fabricate materials with intended properties. While x-rays are typically used on low density metals of small volumes (<1 mm3), proton radiography can be used on large samples (>10,000 mm3), an increase of over four orders of magnitude. In this work, 800 MeV protons at Los Alamos National Laboratory’s (LANL) Los Alamos Neutron Science Center facility and synchrotron x-ray radiography at Argonne National Laboratory’s Advanced Photon Source (APS) were used to interrogate solidification in an alloy of aluminum with 10 atomic percent indium additions. This alloy exists as two separate liquid phases before solidification. In the experiments, fluid flow and structure evolution were monitored. The minority and majority liquid phases behave similarly to oil droplets in water, except that the denser, indium-rich liquid droplets sink instead of floating in the majority aluminum-rich liquid phase. Understanding the complex motion and coarsening of the indium-rich liquid droplets in the melt may provide a methodology to control how the solidification structure develops and allow improved casting quality.

Contact

Amy Clarke

Los Alamos National Laboratory

aclarke@lanl.gov

Funding

DOE Office of Science, Basic Energy Sciences Program through the Early Career Research Program and the Advanced Photon Source User facility, and by NNSA for operation of the LANL Neutron Science Center.

Publications

A. Clarke, S. Imhoff, P. Gibbs, J. Cooley, C. Morris, F. Merrill, B. Hollander, F. Mariam, T. Ott, M. Barker, T. Tucker, W.-K. Lee, K. Fezzaa, A. Deriy, B. Patterson, K. Clarke, J. Montalvo, R. Field, D. Thoma, J. Smith and D. Teter, “Proton Radiography Peers into Metal Solidification”, Scientific Reports, 3, 2020, (2013). DOI:10.1038/srep02020.

Related Links

http://www.nature.com/srep/2013/130619/srep02020/full/srep02020.html

Highlight Categories

Performer: DOE Laboratory , SC User Facilities , BES User Facilities , APS

Additional: Collaborations , NNSA