New Tools to Manufacture Higher-Efficiency Lighting

Understanding how chemical vapors interact leads to better production equipment and increased lighting efficiency.

The Science

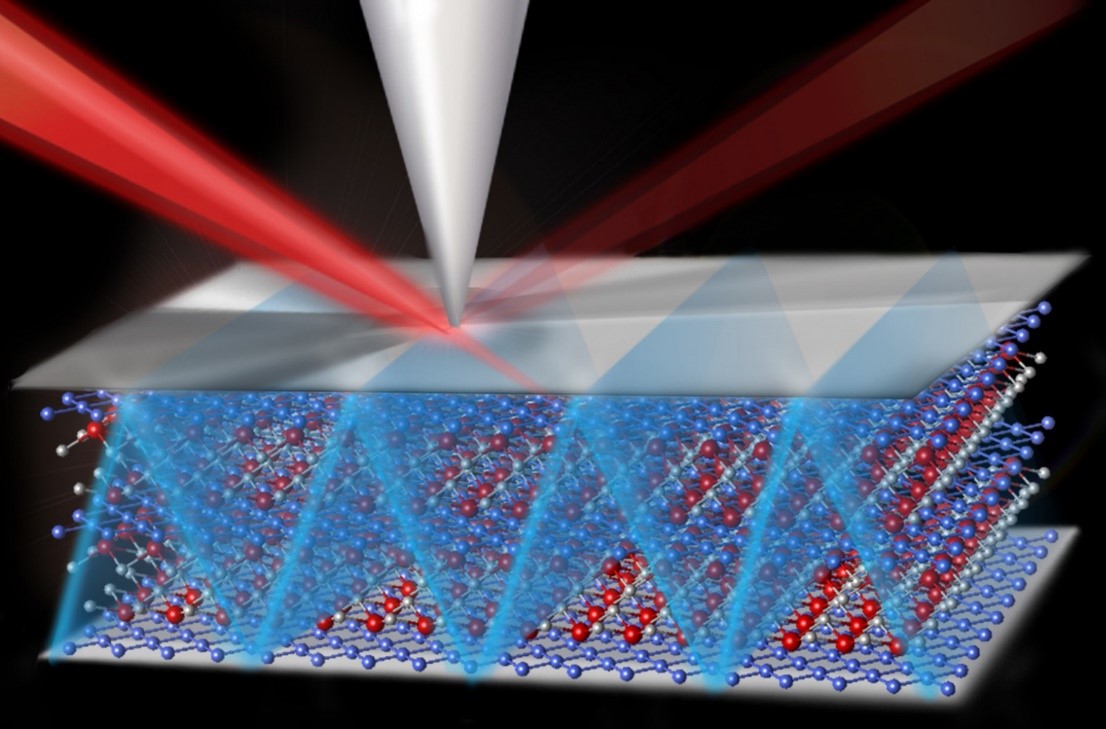

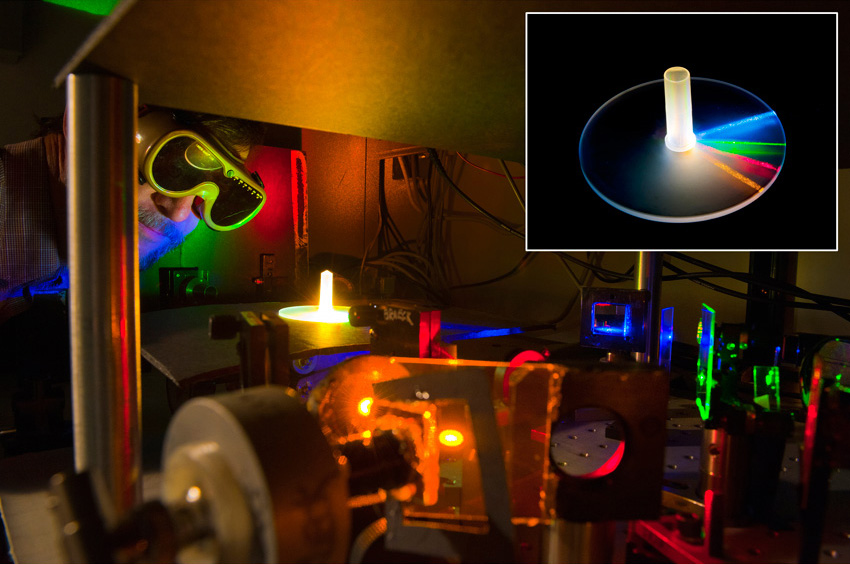

Based on understanding how complex materials are formed from chemical reactants, a new type of growth furnace was designed that controls and characterizes semiconductor crystal growth with unprecedented precision, critical to improving solid state lighting.

The Impact

A rotating disk chemical vapor deposition furnace has been developed and is being used to manufacture commercial, high efficiency solid state lighting materials that will reduce electricity use. This research has demonstrated the precise control and material quality needed to manufacture materials needed for efficient lighting.

Summary

Widespread adoption of solid-state lighting (SSL), which can achieve 50-70% efficiency, could cut lighting-electricity consumption by half, thereby cutting overall electricity use by over 10%. By contrast, fluorescents are limited to about 25% efficiency and incandescents only 6%, with most of the electrical energy converted to waste heat. SSL technology is based on electroluminescence, which results when a particular combination of semiconductors allows electrons to move between different electronic levels of a semiconductor; the associated energy difference is released as photons of light. To enable this chain of events, SSL researchers at Sandia National Laboratories aim to grow nearly perfect semiconductor material, with the goal of producing a photon of light from every single electron that is injected into the device. Growth of electroluminescent semiconductors can be most efficiently accomplished by chemical vapor deposition (CVD), in which hot chemical vapors are used to make semiconductor films. Small changes in temperature, density, geometry of the reactor, and rate of substrate rotation have large affects on the material that forms. Sandia developed a rotating disk CVD reactor that controls these variables and has state-of-the-art measurement techniques to monitor and characterize the films as they are developed. Sandia worked with industry partners including Veeco, Emcore, and K-Space to commercialize these and other tools for the atomically precise manufacture of ever-better materials for ultra-efficient solid state lighting technologies. Most solid-state lighting device manufacturers, including Applied Materials, Aixtron, and Sandia’s partner Philips Lumileds, are presently using these techniques to further develop methods to manufacture a wide array of SSL devices.

Contact

Jerry Simmons, Mike Coltrin, Jeff Tsao, Sandia National Laboratories

Funding

Basic Research: DOE Office of Science, Basic Energy Sciences program

Follow-on Applied R&D: DOE Office of Energy Efficiency and Renewable Energy, Building Technologies program, including several industrial partners, and Sandia National Laboratories Laboratory Directed Research and Development (LDRD) Program.

Publications

M. H. Crawford, “LEDs for Solid-State Lighting: Performance Challenges and Recent Advances,” IEEE Journal of Selected Topics in Quantum Electronics, 15 1028 (2009).

J. R. Creighton, et al. “Emissivity-Correcting Mid-infrared Pyrometry for Group-III Nitride MOCVD Temperature Measurement and Control,” Journal of Crystal Growth 310 1062 (2008).

J.M. Phillips, et al., “Research Challenges to Ultra-efficient Inorganic Solid-state Lighting,” Laser and Photonic Reviews 1 307 (2007).

W. G. Breiland and K. P. Killeen, “A Virtual Interface Method for Extracting Growth Rates and High Temperature Optical Constants from Thin Semiconductor Films using In Situ Normal Incidence Reflectance,” Journal of Applied Physics 78 6726 (1995).

P. Ho, et al., “Laser-Induced Fluorescence Measurements and Kinetic Analysis of Si Atom Formation in a Rotating Disk Chemical Vapor Deposition Reactor,” Journal of Physical Chemistry 98 10138 (1994).

W. G. Breiland and G. H. Evans, “Design and Verification of Nearly Ideal Flow and Heat Transfer in a Rotating Disk Chemical Vapor Deposition Reactor,” Journal of the Electrochemical Society 138 1806 (1991).

Related Links

http://www1.eere.energy.gov/buildings/ssl/

Highlight Categories

Performer: DOE Laboratory , Industry

Additional: Technology Impact , Collaborations , EERE