New Aluminum Alloys for Energy-Efficient Transportation

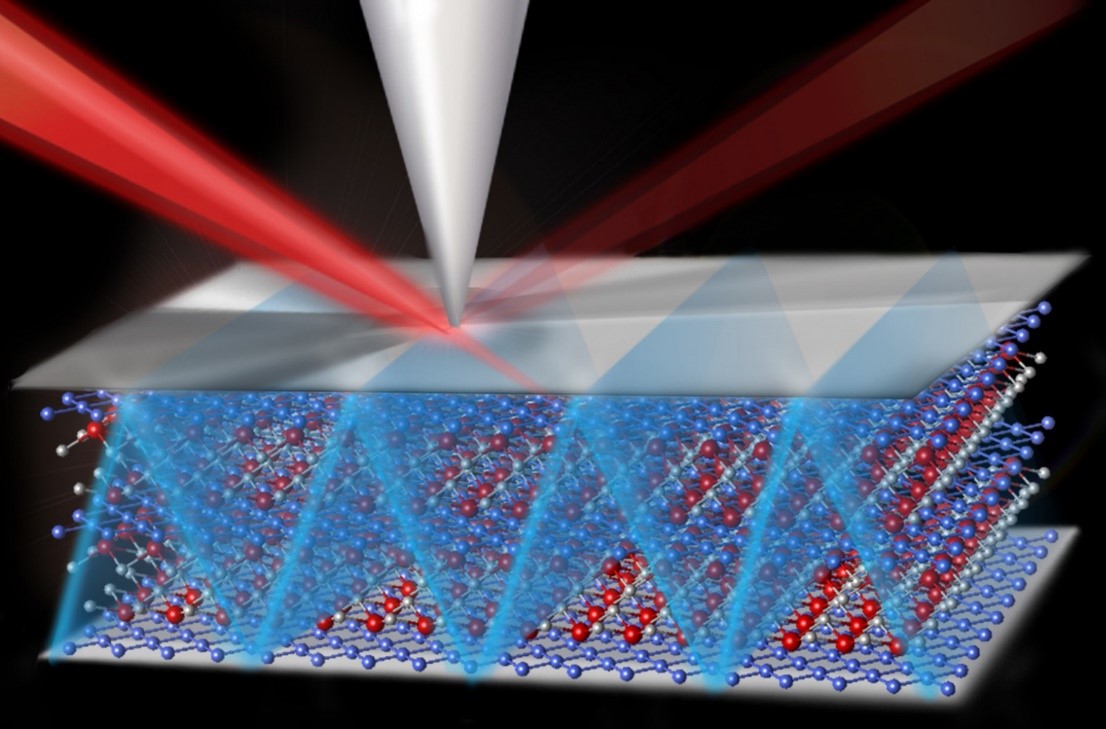

High resolution imaging of atomic structure results in improved design of aluminum alloys.

The Science

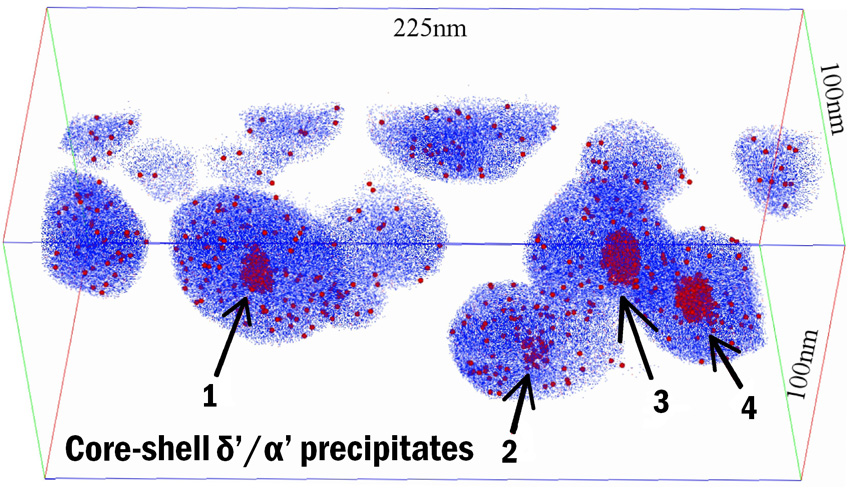

Precise characterization of the nanostructural details in aluminum alloys has enabled the tailoring of precipitate structure and spacing in advanced alloys, resulting in improved materials.

The Impact

Industry is using these new alloys to replace heavier or more expensive materials in vehicles and airplanes; these materials can operate at twice the temperature of previous alloys, resulting in more efficient performance at lower costs.

Summary

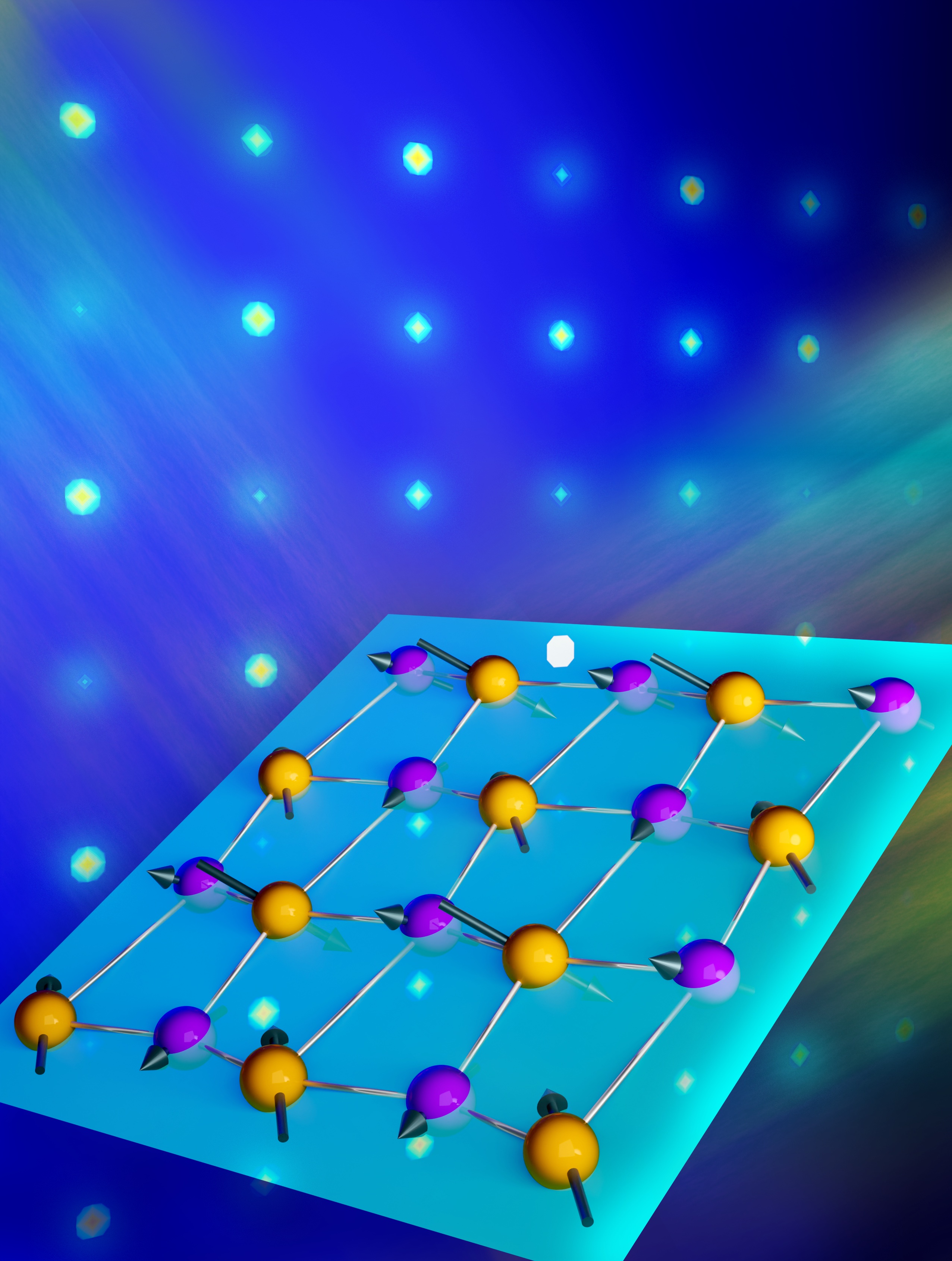

One of the best ways to increase the energy efficiency of our modes of transportation without compromising performance, safety, and consumer preference is to replace parts made with heavy materials with those made with lighter-weight materials. However, the materials used in vehicles must meet precise requirements including strength, durability, flexibility, manufacturability, and heat resistance. Research at Northwestern University has helped develop aluminum alloys that can replace heavy cast-iron and expensive titanium for parts in cars and airplanes. This was achieved by the creation of nano-scale particles in aluminum using trace amounts of highly potent alloying elements like scandium, zirconium, and lithium. By characterizing the placement of these elements in the aluminum alloy following a range of heat treatments, researchers could tailor particle size, spacing, composition, and structure to achieve necessary physical requirements. The strength and heat-resistance of these new alloys makes them ideal replacements for materials in many transportation applications. Translation to US industry is ongoing: an automotive company investigates these alloys as replacement for heavy cast-iron rotors in its cars, and an aerospace company is examining their use as replacement for expensive titanium heat-shield brackets.

Contact

David Seidman and David Dunand, Northwestern University

Funding

Basic Research: DOE Office of Science, Basic Energy Sciences program

Publications

D.N. Seidman, E.A. Marquis, D.C. Dunand. “Precipitation strengthening at ambient and elevated temperature of heat-treatable Al(Sc) alloys”. Acta Materialia. 50 (2002): 4021-4035

M.E. Krug, D.C. Dunand, D.N. Seidman. “Composition profiles within Al3Li and Al3Sc/Al3Li nanoscale precipitates in aluminum”. Appl. Phys. Letters. 92(2008):124107

Related Links

http://arc.nucapt.northwestern.edu/Seidman_Group

Highlight Categories

Performer: University

Additional: Technology Impact