Facilities

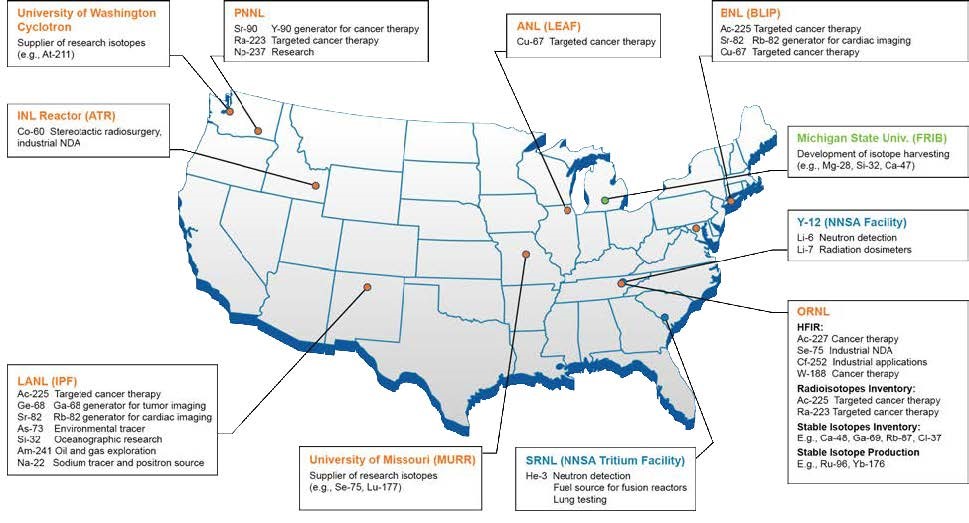

The Department of Energy (DOE) Isotope R&D and Production Program (IP), managed by the Office of Science, leverages national laboratories and universities to provide the Nation with critical isotopes in scientific, medical, security, and industrial applications. These institutions represent a globally unique capability coordinated by the DOE IP to produce and distribute radioactive and stable isotopes that are a key facet of ensuring Nation’s security and prosperity. The sale and distribution of isotopes is coordinated through the National Isotope Development Center (NIDC), which is managed by the DOE IP. A robust portfolio of cutting-edge R&D activities not described below at these and many other institutions that continue to push the boundaries of isotope production and enable new applications of radioactive and stable isotopes is also stewarded by the DOE IP.

Map of the DOE IP isotope production sites spread throughout the continental United States.

National Laboratories

Argonne National Laboratory (ANL)

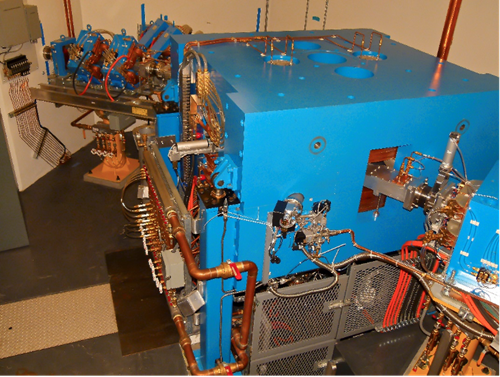

The Low-Energy Accelerator Facility, or LEAF, at Argonne National Laboratory combines an electron linear accelerator to enable radioisotope production with a Van de Graaff (VDG) electron accelerator to study radiation effects. The Argonne Radioisotope Research and Production Program (R2P2) performs a wide range of radioisotope separation, purification, and targetry method development and uses the LEAF for radioisotope production (including theragnostics copper-67 and scandium-47), radiation testing and material response to received dose, and material activation studies. Since its construction in 1969, the LEAF has undergone significant improvements to boost the beam power and energy, now operating at energy up to 50 MeV and beam power up to 25 kW.

The LEAF’s Linac component can deliver continuous or pulsed beams with energies up to 50 MeV and average power exceeding 20 kW at energies relevant to radioisotope production. It is equipped with multiple target station locations that facilitate remote operations and post-run target transfer. Its counterpart, the low-energy (3 MeV) VDG electron accelerator, can deliver high levels of electron and photon dose rates (in pulsed or continuous mode) to critical components to test for radiation hardness and stability while avoiding activation and handling hazards of the irradiated targets. The R2P2 utilizes ANL’s hot cells, radiochemical laboratories, and the Analytical Chemistry Laboratory to aid in separations, processing, and purity analysis activities.

Brookhaven National Laboratory (BNL)

Built in 1972, the Brookhaven Linac Isotope Producer facility, or BLIP, at Brookhaven National Laboratory consists of a 30 m beam line and target area that shares protons up to 200 MeV and 165 µA with BNL’s nuclear physics program at the Relativistic Heavy Ion Collider. Protons are directed at specific target materials, enabling the production of a variety of isotopes for distribution to the nuclear medicine and industrial communities for research and commercial purposes. BLIP is also used for R&D of new and improved isotope production capabilities and to perform non-isotope irradiations such as materials research.

Once targets are irradiated in a water-cooled holder, they are raised from the accelerator vault to a hot cell with remote handling. Next, the irradiated targets are appropriately packaged and transported on-site to a dedicated hot cell processing facility that includes eight radiochemistry development labs, nine lead and steel hot cells, and an instrumentation lab for radionuclide and elemental assay.

Production of isotopes in the BLIP is dependent upon the operating cycle of the Linac. The schedule and duration of Linac operations are determined by the plans and funding of the nuclear physics experiments. Key isotopes commonly in production at BLIP include actinium-225 and copper-67.

Idaho National Laboratory (INL)

Designed and constructed in the 1960s, the INL Advanced Test Reactor, or ATR, is the only U.S. research reactor that offers large-volume, high-flux neutron irradiation in a prototype environment, making it a prime candidate for studying the effects of intense neutron and gamma radiation on reactor materials and fuels. The 250 MW reactor operates at low pressure and low temperature with a high neutron flux up to ~4.4 × 1014 neutrons/cm2/sec. The reactor is cooled by light water with a beryllium reflector for high neutron efficiency.

The ATR can accommodate an extensive range of irradiation testing. It is equipped with a unique serpentine core that allows the reactor’s corner lobes to be operated at different power levels, making it possible to conduct multiple simultaneous experiments under different testing conditions. Other key characteristics include large test volumes, up to 48 in. long and 5 in. in diameter; 77 testing positions; fast/thermal flux ratios ranging from 0.1 to 1.0; constant axial power profile; power tilt capability for experiments in same operating cycle; frequent experiment changes; and seismic shutdown system that can automatically shut down the plant if certain levels of seismic activity are detected.

The ATR produces cobalt-60, the medical radioisotope used in Gamma Knife® treatments of brain tumors and is expanding its production to other medical and industrial isotopes.

Los Alamos National Laboratory (LANL)

Commissioned in 2004, the Isotope Production Facility, or IPF, at LANL routinely produces radioisotopes at beam currents up to 275 µA using the 100 MeV proton beam generated at the front end of the Los Alamos Neutron Science Center (LANSCE) accelerator. Resulting high-purity, high-specific-activity isotopes— including actinium-225, sodium-22, and arsenic-73—are utilized across the fields of medicine, fundamental nuclear physics, national security, environmental science, and industrial applications.

The IPF’s water-cooled target holder contains space for three targets, allowing for simultaneous proton-based production in three different energy ranges, as well as the availability of activation of small targets by the high energy secondary neutron flux. Targets are processed at the hot cell facility in the nearby radiochemistry complex. This complex is equipped with 13 hot cells, as well as radiological and analytical laboratories and packaging operations. The Hot Cell Facility is where chemical processing occurs to isolate the desired isotope products suitable for use by customers. The IPF and Hot Cell Facility are also used to perform research to explore production and separation of novel radionuclides, including the collection of production-related nuclear data.

The DOE IP also leverages nuclear material recycling activities at LANL that produce americium-241.

Oak Ridge National Laboratory (ORNL)

ORNL produces, purifies, and ships more than 300 stable and radioactive isotopes used in medicine, research, industry, and space exploration. The High Flux Isotope Reactor (HFIR) at ORNL provides the highest continuous neutron flux in world and is used to produce neutron-rich isotopes, such as californium-252. ORNL is also home to several nuclear and radiological facilities housing a suite of radioisotopes processing capabilities. ORNL is also home to electromagnetic isotope separator and gaseous centrifuge capabilities for producing enriched stable isotopes.

In operation since 1965, HFIR is one of the most versatile irradiation facilities in the world. It was constructed to meet the production needs of transuranic isotopes of heavy elements like californium and curium, but it's mission also includes materials irradiation, neutron activation, and neutron scattering. Operating at 85 MW, HFIR is one of the highest flux reactor-based sources of neutrons for condensed matter physics research in the United States, and it provides one of the highest steady-state neutron fluxes (up to 2.5 × 1015 neutrons/cm2/sec) of any research reactor in the world. The thermal and cold neutrons produced by HFIR are used to study physics, chemistry, materials science, engineering, and biology. The intense neutron flux, constant power density, and constant length fuel cycles are used by more than 500 researchers each year for neutron scattering research into the fundamental properties of condensed matter and other in-core experiments.

The reactor is beryllium-reflected, light-water-cooled and moderated, and uses highly enriched uranium-235 as fuel. Operated cycles at HFIR last approximately 25 days, and seven cycles are typically conducted each year. Key isotopes routinely produced at HFIR include californium-252, nickel-63, selenium-75, actinium-227, and strontium-89.

HFIR's in-core irradiation capabilities allow experiments and isotope production capsules to be placed in a wide variety of positions. With HFIR's mission expansion, many new experiment facilities have been built, including four horizontal beam tubes, originating in the beryllium reflector; the hydraulic tube irradiation facility and two pneumatic tube facilities that enable insertion and removal of samples during operation; 30 target positions in the flux trap; six peripheral target positions on the outer edge of the flux trap; numerous vertical irradiation facilities ranging in size spaced throughout the reflector; and two slant access facilities, or "engineering facilities," around the edge of the reflector.

ORNL’s Enriched Stable Isotope Prototype Plant (ESIPP) was constructed to aid in the replenishment of the nation’s inventory of enriched stable isotopes, which had not been produced since 1998 when calutrons at the Y-12 National Security Complex were placed on “standby” mode. ESIPP is composed of two key types of instruments, namely the electromagnetic isotope separator (EMIS) and the gas centrifuge isotope separator (GCIS).

To date, ruthenium-96 has been produced and delivered to customers using EMIS, and the NIDC and DOE continue to develop priorities for new production campaigns. A project to expand the plant for enriching larger quantities of isotopes using GCIS technology is in progress. The expanded plant, referred to as the Stable Isotope Production Facility, will be a significant new investment in support of research requiring large quantities of enriched stable isotopes not readily available from other sources.

Pacific Northwest National Laboratory (PNNL):

At PNNL’s Radiochemical Processing Laboratory (RPL), experienced staff use state-of-the-art facilities and specialized instrumentation to prepare high-quality radioisotopes for use in medical, research, and national security applications. For example, the team holds expertise in ultra-pure radiochemical separations techniques used to make generator systems for lead-212/bismuth-212 and strontium-90/yttrium-90, both of which are used in drugs for the treatment of various cancers. Radium-223 and thorium-227 are also produced at the RPL for use in targeting cancer-related complications.

Staff at the RPL utilize shielded facilities, including hot cells, to conduct work with radioactive materials ranging from bench-scale to pilot-scale experiments. Such work includes analytical chemistry operations, advanced analytical methods development, isotope processing, advanced separations, reactor fuel handling, and nuclear materials examination.

Savannah River National Laboratory (SRNL)

At the Savannah River Site (SRS) tritium facilities, operated by the National Nuclear Security Administration (NNSA), tritium is replenished continually to maintain the Nation’s supply by recycling it from existing warheads and extracting it from target rods irradiated in Tennessee Valley Authority nuclear reactors. Its replenishment is necessary because the isotope decays to helium-3 at a rate of 5.5% each year. Because helium-3 is a valuable commodity in non-weapons-related applications, notably in neutron detection equipment, DOE has arranged for the DOE IP to coordinate its sales and distribution.

Y-12 National Security Complex (Y-12)

The Y-12 National Security Complex enables the DOE IP to offer enriched lithium-6 and lithium-7.

As an NNSA facility, Y-12 is tasked with producing and supplying lithium isotopes of which the excess is distributed by the NIDC for non-weapons applications. DOE has made the excess of both lithium-7 and lithium-6 isotopes available to industry for research and other purposes, including neutron detection and radiation dosimetry.

Universities

The DOE IP leverages the unique capabilities of several universities throughout the Nation to produce isotopes for sale through the University Isotope Network (UIN). The UIN currently consists of University of Alabama – Birmingham, University of Missouri, and University of Washington.

University of Alabama at Birmingham (UAB)

The University of Alabama at Birmingham Cyclotron Facility houses a variable energy TR24 cyclotron capable of accelerating protons from 16-24 MeV with currents of up to 300 uA. The cyclotron has four beamlines and associated target stations and produces a wide variety of radioisotopes including Zr-89, Cu-64, Sc-43, Sc-47, Ti-45, Co-55, Mn-52, V-48, and others. The highly trained staff can accommodate special requests and are DOT certified for national and international shipping.

Additionally, the cyclotron facility contains hot cells used to prepare human-use and preclinical radiopharmaceuticals and associated radiochemistry synthesis and radioanalytical equipment. The UAB Cyclotron Facility hosts visiting scientists and trainees for studies with short-lived isotopes where shipping may not be possible or where additional infrastructure is required.

University of Washington (UW)

In 2016, research staff at the UW Medical Cyclotron Facility began routinely producing radioisotopes for the DOE IP, primarily the alpha particle-emitting astatine-211, used for cancer treatment research. Its short half-life, combined with a lack of cyclotrons capable of producing high-intensity alpha particle beams, has limited the global availability of astatine-211 in the past, and UW’s unique facility helps to alleviate this demand.

The facility is equipped with a Scanditronix MC50 compact cyclotron that is a fully tunable (with respect to beam energy and current) multi-particle instrument capable of accelerating proton, deuteron, helium-3, and alpha particle beams. Conditions for astatine-211 production at the Medical Cyclotron Facility include a 29 MeV alpha beam with 50 of beam current. The facility also contains two target stations inside the accelerator vault for radionuclide research.

University of Missouri (UM)

For more than 50 years, the University of Missouri Research Reactor (MURR®) has promoted ground-breaking research and life-saving radiopharmaceuticals, providing benefits to people around the world. MURR is the highest-power university research center in the U.S., operating at 10 megawatts, 6.5 days a week, 52 weeks a year. This routine reliability makes the MURR facility an essential resource for researchers, scientists, engineers, and students across the country. In a typical year, MURR supplies more than 35 different isotopes and send out more than 2,000 shipments.

MURR is equipped with more than 25 different irradiation positions spanning numerous neutron fluxes and geometries. The facility houses state-of-the-art hot cells, shielded glove boxes, clean rooms, and laboratories needed to reliably meet the demand for radiopharmaceutical products and industrial radioisotopes.